Phonoflex® is completely recyclable!

ACOUSTICS IN BRIEF

The sound absorbent capacity of materials is quantified through the sound absorption coefficient αw, which is defined as the ratio between the absorbed sound power and the incident sound power.

The α value thus represents the fraction of sound energy absorbed by a given material and may vary between 0, if all the incident energy is reflected, and 1, if all the incident energy is absorbed. Consequently, if the value of α is 0.3, this means that 30% of the energy incident on the surface of the material is absorbed.

Nevertheless, for a specific material, the α value may vary according to the single frequencies and angle of incidence of the sound wave; for the sake of simplicity, the absorption coefficients are expressed as a function of the frequency in octave bands or one-third octave bands.

The Phonoflex® sandwich panels absorb sound and thus improve the acoustics of the environment in which they are installed, attenuating noise reverberation. In addition, by acting principally on the frequencies of speech, they make it more intelligible. Their numerous applications make them suitable for environments that require an improvement in sound quality, so that they can be used for a broader range of applications: cinemas, concert halls, conference and meeting rooms, offices and theatres.

MATERIALS AND FINISHES

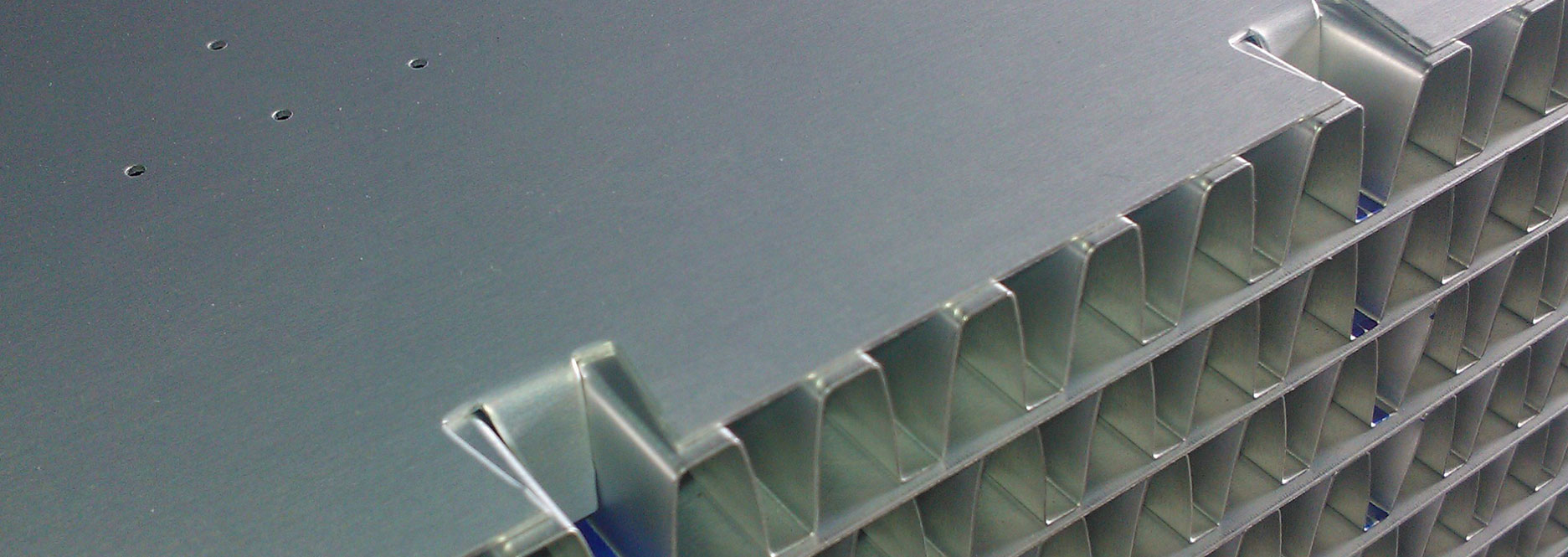

Phonoflex® can be produced with various surface finishes including anodized aluminium, sublimed aluminium, digitally printed aluminium , prepainted sheet metal and stainless steel. The Phonoflex® sound absorbent sandwich panel can be covered with PVC adhesive films so as to obtain a smooth surface with a negligible effect on its sound absorbent capacity; a few layers of porous materials (e.g. mineral wool) can also be fitted to the back of the panel to give Phonoflex® soundproofing as well as sound absorbent properties.TECHNICAL CHARACTERISTICS

Material: Aluminium

Width: 900 mm

Length: 3000 mm

Weight: 7.8 Kg/m2

Nominal thickness: 20 mm

Actual thickness: 20.2

Thickness of perforated leather: 1 mm

Thickness of rear skin: 1 mm

Thickness of corrugated sheet: 0.3 mm

Diameter of holes: 2 mm

Horizontal pitch: 16.6 mm

Vertical pitch: 18 / 36 / 72 mm

Number of holes per m2: 1944

Drilling percentage: 0.60%

Mean absorption coefficient: 0.27Notes:

The values indicated above apply to the standard panel. On request, these characteristics can be modified to guarantee the result best suited to specific environmental conditions and acoustic requirements.

Standard tolerance limits on the thickness of the product +/- 0.5 mm.

Standard tolerance limits on the width and length of the product +/- 1 mm.